Services

Engineering

service

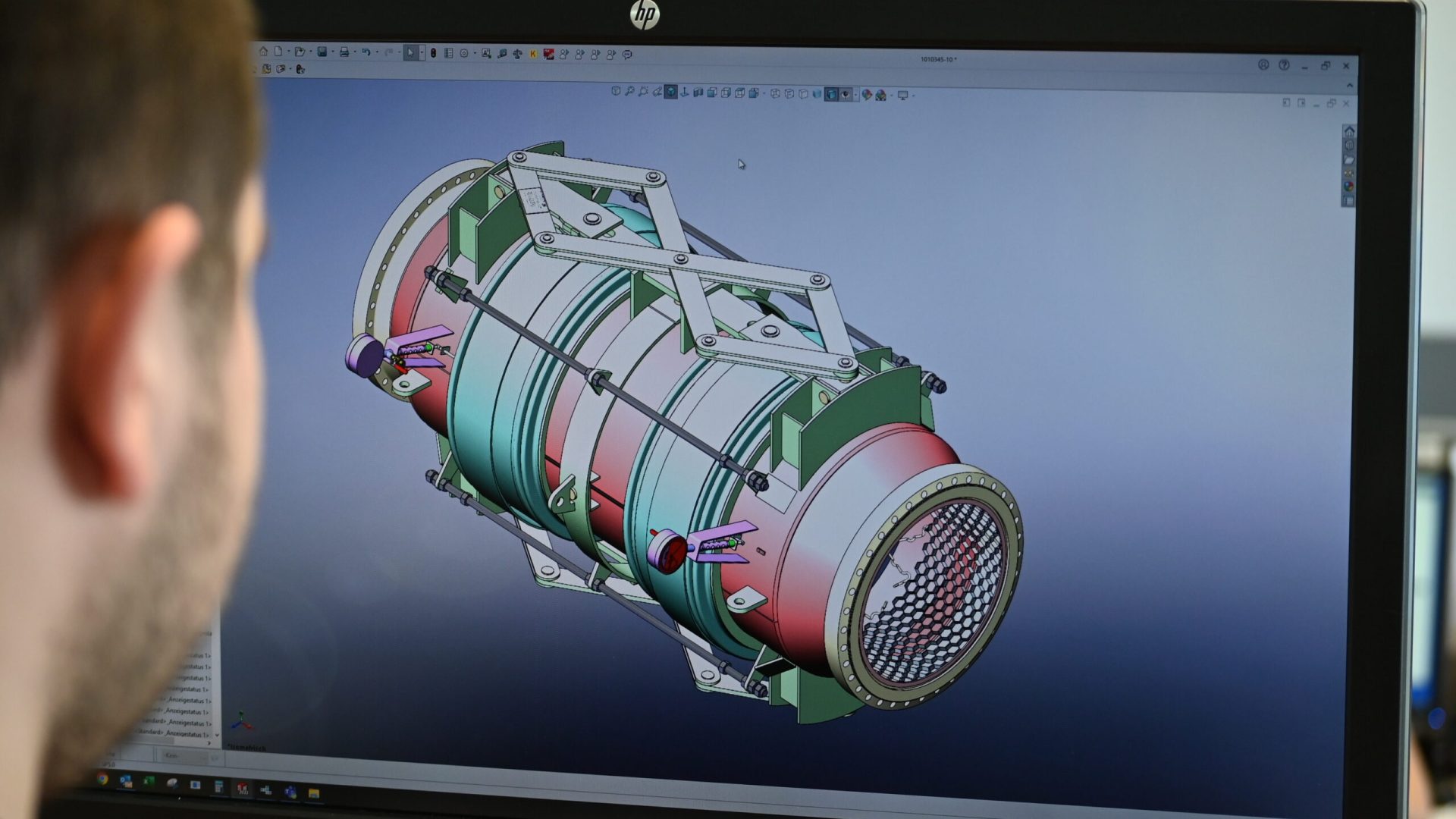

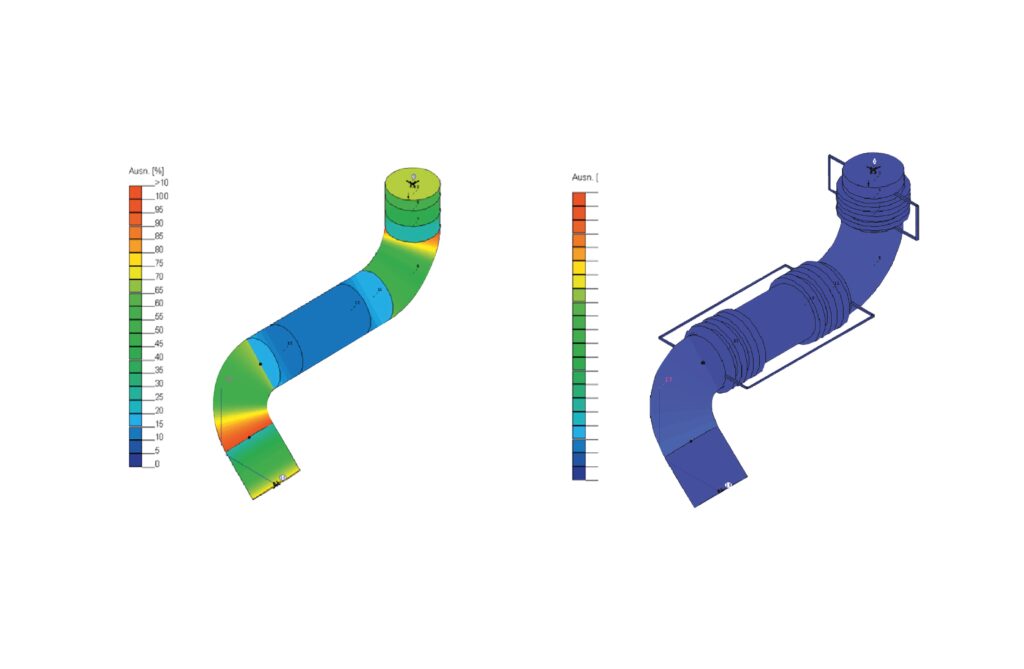

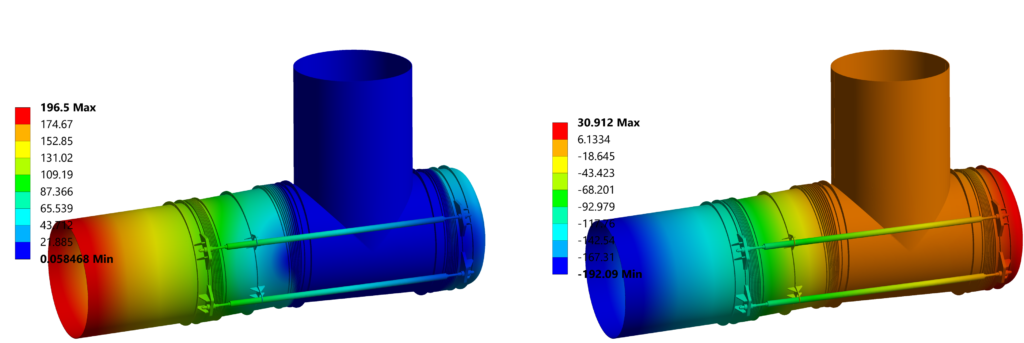

Our specialized engineering team designs and analyses the expansion joints in close collaboration with the customers and accompanies them through every step of the project. We support our customers in the selection of the most suitable materials and the optimization of movements and number of cycles. Thanks to the latest software, all types of expansion joints, as well as entire piping systems, can be calculated and optimized. Our service includes, but is not limited to, design studies for expansion joints, FEAM (Finite Element Analysis Methode) and piping calculation (ROHR 2).

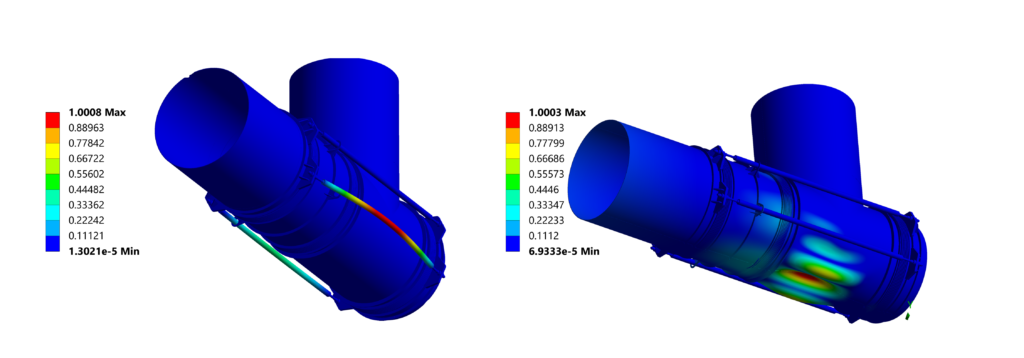

Excessive stresses in the pipe section

Reduced tension through the use of tensioned expansion joints

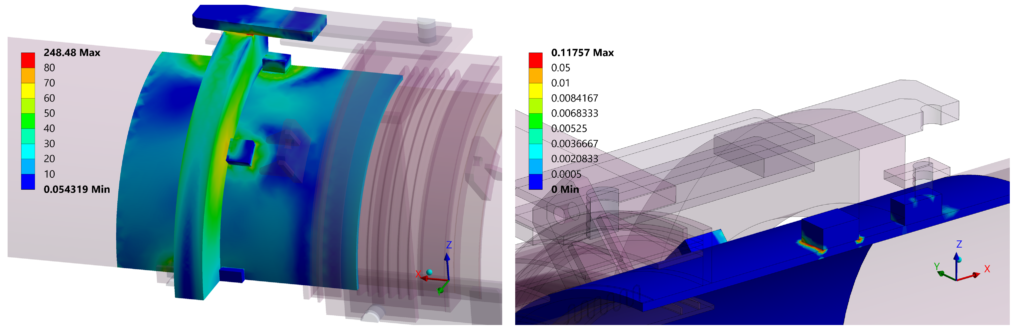

Structural mechanical analysis, strength verification according to ASME VIII-2

Linear buckling analysis with finite element method

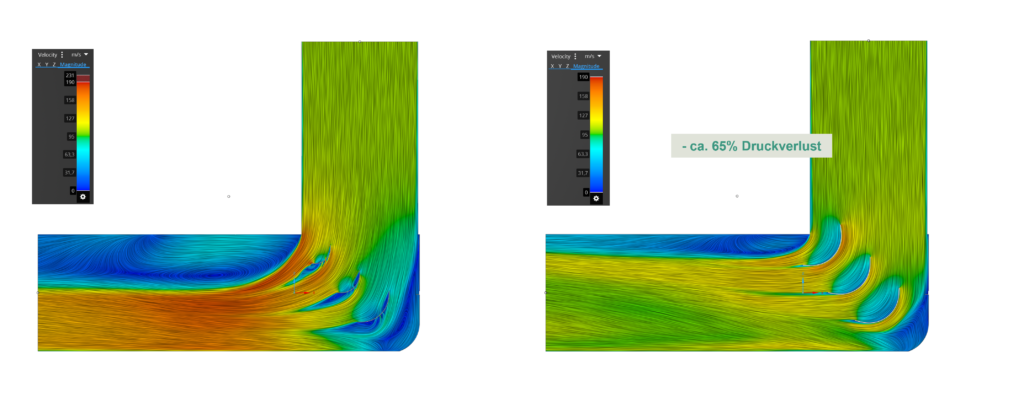

CFD (Computational Fluid Dynamics) analysis, optimization of the baffles

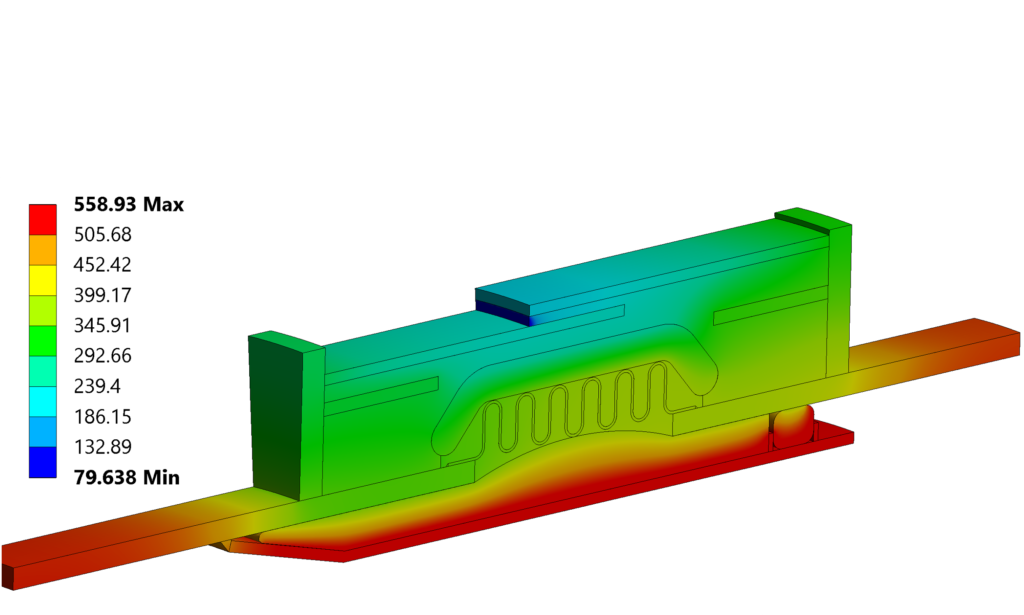

Thermal analysis

On-site

service

We support our customers by offering a variety of on-site services throughout the life of the expansion joint: supervision of on-site expansion joints, inspection of all types of expansion joints, installation and welding of expansion joints and clamshell bellows.

Express

Since production stoppages cannot always be planned and predicted, kompaflex specializes in the rapid manufacturing of all types of expansion joints. This is made possible by a large stock of materials, including special alloys, and a highly flexible production line.

Special transport

We arrange the transport of expansion joints to the construction site or the customer’s warehouse worldwide. With deliveries to over 90 countries, we can provide cost effective freight logistics solutions to our customers. Our logistics department is vastly experienced in organizing oversized loads, sea freights, air freight and road freight.

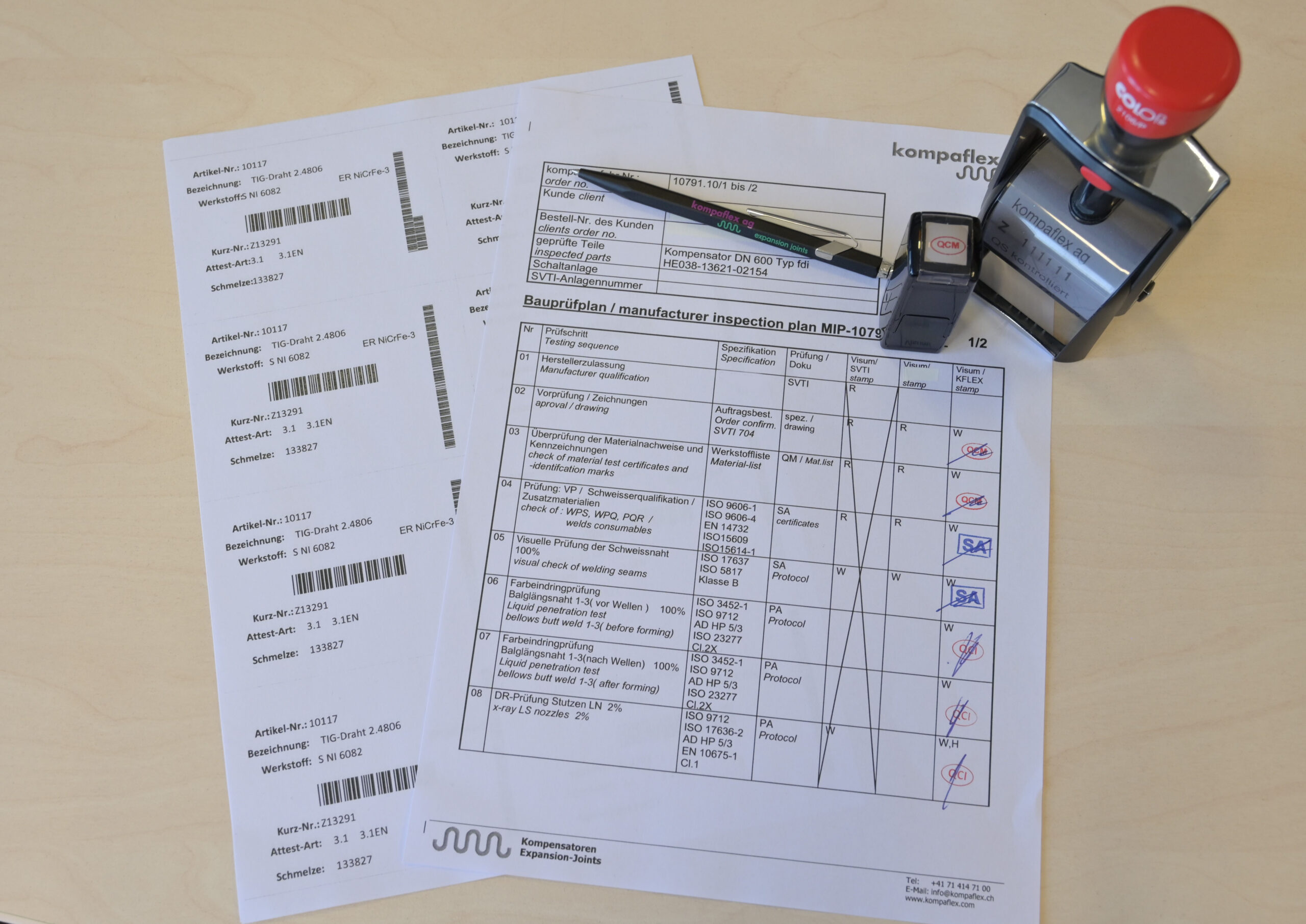

Documentation

Proof of product quality in written form for the final documentation has become an essential aspect of the product. Depending on the relevant authorities and client specifications, the included documentation covers all necessary quality certifications, such as proof of all tests carried out, material certificates and personnel qualifications. Final documentation of expansion joints that fall under the Pressure Equipment Directive are reviewed by notified bodies. We fulfill the requirements individually according to the customer’s needs and specifications. Our documentation department works closely with quality management and the testing team